Corrosion resistance is an important property requirement for materials used in the manufacturing of automobiles, particularly for vehicles that operate on roads treated with de‐icing salt. This implies to test the corrosion resistance of automotive systems, in order to make a good selection of materials. Field‐tests, including stationary and mobile exposures are normally the most reliable ways of doing this, but they are costly and time consuming, as 2–8 years exposure is generally needed for a full assessment of the corrosion resistance. Since, the use of the standard neutral salt spray test, which is well known to give a poor correlation with field data, a large development in the testing procedures has occurred with the use of cyclic corrosion tests, which alternate between pollution phase and wet/dry periods. Today, there are indeed as many accelerated corrosion tests as automotive manufacturers, which are currently used in order to develop and qualify new products against corrosion, to develop new protective coating systems and select materials.

At Vaidic we undertake Corrosion testing exactly as per set standard conditions. Some of the tests are :

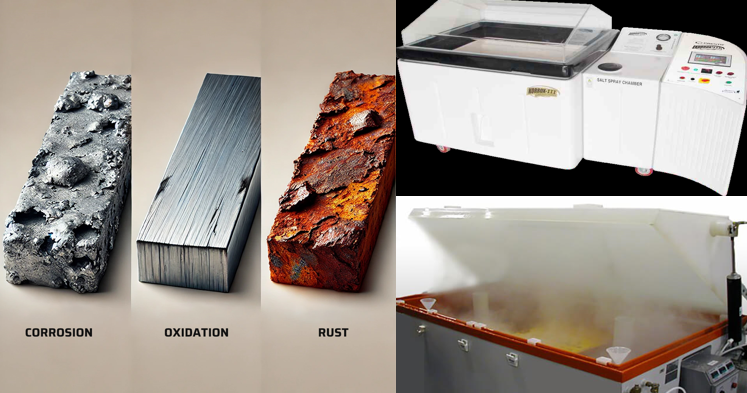

Salt Spray (Neutral / Fog), ASTM B117 and CASS test

Instrumentation : Salt Spray Test Apparatus, CASS Test Apparatus